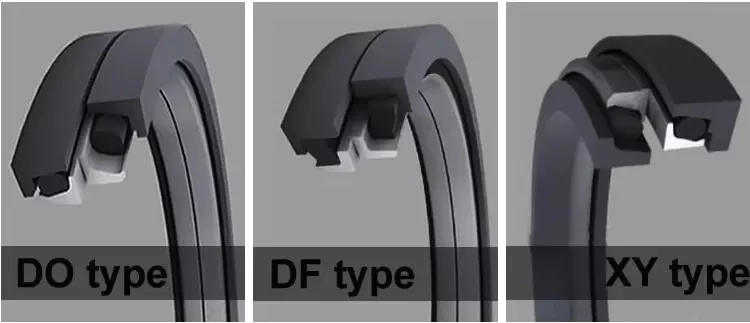

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Mechanical face seal GNL 3767 floating seal supplier

| OEM part# | GNL 3767 |

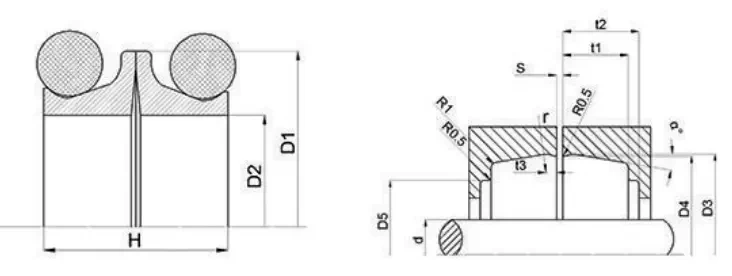

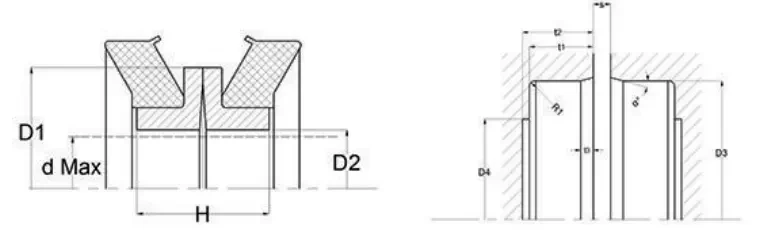

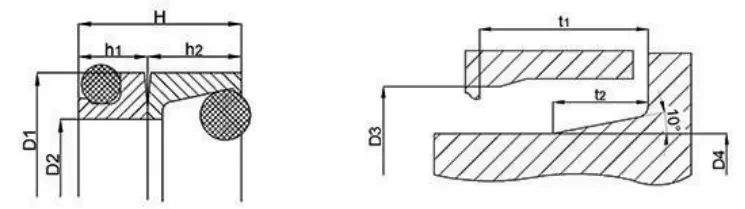

| One set | Consists of two metal sealing rings and two rubber rings |

| Material | 100CR6 steel + NBR60 |

| Warranty | 18 months |

| Stock | Available |

| FOB | Wuhan ,Shanghai ,Qingdao ,Ningbo ,Shenzhen ,Xiamen |

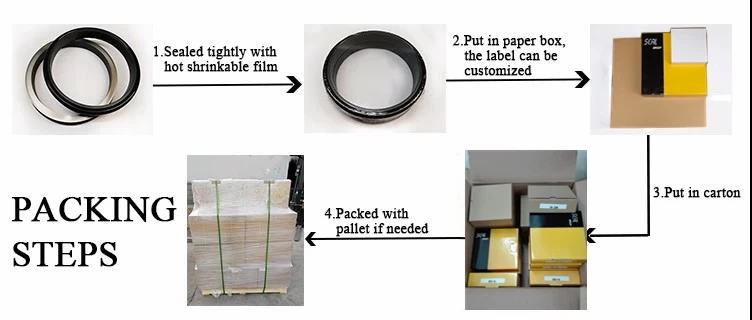

| Package | Shrink films + inner box + standard export carton + wood pallet + wood box |

| Application | Constuction machinery ,farm machinery ,coal mining machinery |

|

Mechanical face seals are precision components, the smallest of material and design details can influence the quality.The metal ring is processed by CNC machine,the fine precision increase O-ring gripping ability,eliminating O-ring sliding,ensure runs smoothly. |

| Polishing attained by lapping process.The surface flatness of Rvton products is within 3 light bands of Optical interference of monochromatic light., our standard of the working surface roughness is ≤Ra 0.1μm |  |

| METAL | Steel Gcr15/ 100Cr6 | Cast 15Cr3Mo |

| Surface smoothness/roughness | ≤Ra0.2μm | 6.3-12.5μm |

| Work face smoothness | ≤Ra0.15μm | ≤Ra0.1μm |

| Pressure loading | ≤0.15MPa | ≤0.3 MPa |

| Forging line speed | 2m/s | 3m/s |

| Temperature range | -100~200°C | -40~160°C |

| Hardness (HRC) | 58-62 | 62-68 |

| Lifetime (Hours) | 3000-5000 | 5000-8000 |

| Material | NBR60 | SILICONE | FKM |

| Hardness | 60°-65° | 60°-65° | 72°-78° |

| Minimum tensile strength | 11MPa | 10.6MPa | 11MPa |

| Minimum elongation at break | 300% | 400% | 260% |

| Permanent deformation | 12% | 8% | 25% |

| Temperature range | -42℃-120℃ | -49℃-230℃ | -30℃-250℃ |

| Specific Gravity | 1.25 | 1.2 | 1.8 |

-Heavy Industry: Mining, Construction, Agriculture

-Tracked Vehicles: excavators, bulldozers, tractors, trucks ...

-Axles

-conveyor system

-Tunnelbohrmaschine

-Travel Engines, final drives, track rollers, idlers ..

|

| Machines | Part# |

| Komatsu numbers | 110-30-00085 110-30-00045 141-30-00610 140-30-00040 140-30-00141 170-30-00110 170-30-00210 175-30-00070 175-30-00700 20Y-30-00040 130-27-00020 150-27-00025 150-27-00026 150-27-00027 204-30-00041 20Y-30-00100 150-30-00035 154-30-00035 154-30-00830 154-30-00832 154-30-00833 170-27-00010 198-30-00072 21T-30-00110 198-30-00072 423-33-00020 423-33-00021 205-30-00052 14X-27-00100 205-30-00050 22B-30-00030 195-27-00022 175-27-00120 175-30-00900 20Y-30-00430 22U-30-00060 20Y-30-13210 204-30-00100 198-30-00140 195-27-00100 568-33-00016 TZES 100-154S |

| Caterpillar numbers | 9G5311 9W6666 1M8747 9W6647 5M1176 6T8433 9G5315 9W6671 9W6680 9W7220 8E5609 9W7225 6P3595 9G5345 9W6690 9W6691 9W7216 2M2858 9W7223 9W6691 1P7249 5P7146 9W7243 7M0481 5P0204 7T0159 9W6651 9W7233 7T0157 108-6997 5P0373 9W7213 9P9663 8E2042 9W6694 9W3732 9W7201 9W7202 9W6620 9W6619 9W3956 169-6442 6Y0855 9W7204 6Y0856 9G5349 3144128 205-9025 9W7204 6Y0856 9G5349 1796862 1796863 145-6034 9W6644 9W6822 3T6602 365-4920 2627244 3176441 9W7206 1796864 1C9748 1456035 3144130 1791292 |

| Hitachi numbers | 4176379 4110358 4128201 4508192 4128201 4508192 4060222 4110359 4512571 4060225 4047279 4104605 4110360 4153468 4163731 4068433 4153711 4163711 4110362 4153732 4508193 4056360 4111361 4507221 4642180 4110366 4110367 4513173 4092483 4082631 4110368 4110369 4114753 4634693 4514259 4179741 4066695 4317584 4138544 4082698 ZAX200-5G XKAH-00916 XKAQ-00219 XKAH-01012 4245703 4200413 4350347 4344155 4082698 |

| Kobelco numbers | 58845-01500 R45P0018D2 R45P0018D3 TD00348/17 R45P0018D4 5691020160 MT4000-7918 R45P0018D6 JB5680 619-89900440 71418383 05/9038111 180-00512 CR3069 XZ993774 MT40211881 R45P0018D21 R45P0018D25 TD0352/04 0964294 5691020340 5691020530 R45P0018D12 2445Z1110 R45P0018D27 TD00611/02 R45P0018D13 UK 5500 R45P0018D14 R45P0018D14 204-50805000 R45P0018D29 RG-30 OK5110H-25 JB5820 619-95032001 R45P0018D20 760S247F JS2650S YN53D00008S023 LQ15V00020S067 R45P0018D22 760S297FS YN15V00037S029 11.3209 24100U1743S24 R45P0018D23 58845-20500 U14568 45P0018D18 R45P00018D9 988430 R45P0018D9 20306 U16184 2445Z1109 HEL-127 A2 |

|

By sea---Heavy cargo by container transport, FOB Wuhan ,Shanghai ,Qingdao ,Ningbo ,Shenzhen ,Xiamen Port. Air to the port---For goods above 100KG, it is economic choice for customers. International Express---Such as DHL,TNT, FEDEX,UPS,EMS and so on.It is the best choice for sample order.Your consignee account is welcome. |