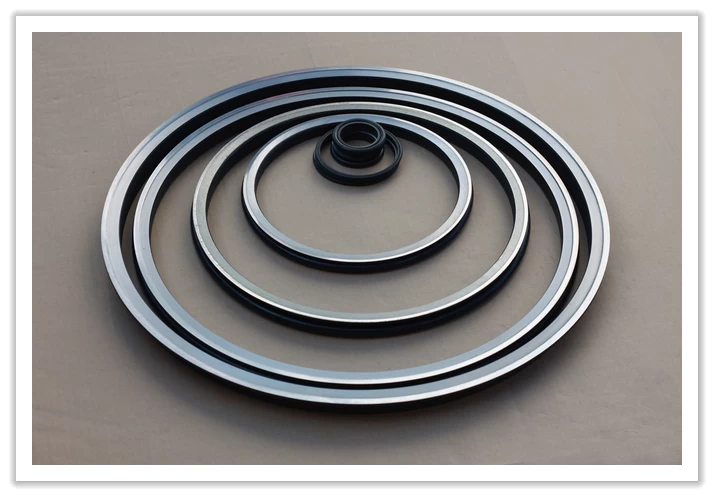

Forge and Cast iron, which do you choose for Floating seals ?

• Gcr15/ 100cr6(1.3505) /E52100 / 534A99/ SUJ2

GCr15 is a kind of high carbon chromium

bearing steel, alloy content is less, with good performance, the most widely

used

Surface smoothness / Roughness:≤Ra0.2μm

Work face smoothness ≤Ra0.015μm

Pressure loading ≤0.3MPa

Forging line speed: 2m/s

Casting line speed: 3m/s

Temperature range: —100~200℃

• 15Cr3Mo high

Cr cast iron

15Cr3Mo pearlitic steel heat-resistant steel, has a high heat resistance

and oxidation resistance at high temperatures, and have some resistance to

hydrogen corrosion. Since the steel contains a high content of Cr, C, and other

alloying elements, hardened steel obvious tendency, poor welding.