Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

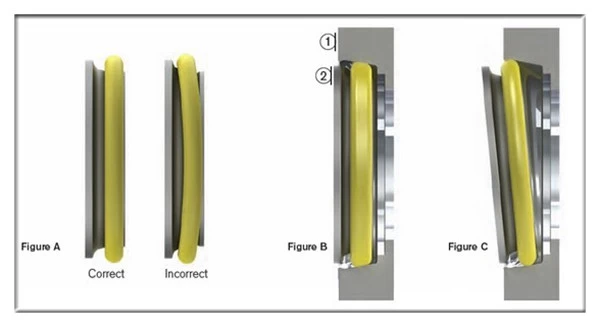

1. Before installation, check the floating oil seal carefully. If the oil seal has lip damage, nicks, scars, cracks, oily corrosion, etc., you need to update the new oil seal in time.

2. After removing the oil seal, check the condition of the shaft journal to see if there are scars and the surface is rough. If there are serious scars on the journal surface, it will cause the oil seal lip and the journal surface to not fit tightly, which will affect the sealing performance and cause oil leakage.

3. During the installation process, it is necessary to do a good job of cleaning, keep the oil seal and journal surface clean, to ensure the sealing installation effect.

4. In special circumstances, tools must be used to prevent the oil seal from being stretched, deformed or scratched.

In order to ensure the sealing effect of floating oil seals, in addition to correct installation, it is necessary to do daily maintenance to extend the service life of floating oil seals and ensure the sealing effect of equipment.