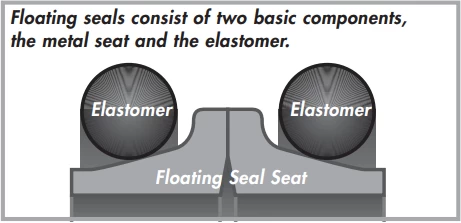

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal Seat Material

Special corrosion-resistant cast iron alloy

O-Ring Elastomer Materials

Nitrile (NBR)

Description: Commonly used because of its good

mechanical properties and low cost, standard nitrile

is also known as Buna-N. It has excellent resistance

to petroleum-based oils and fuels, water and alcohols.

Nitrile also has good resistance to acids and bases,

except those with a strong oxidizing effect.

Limitations: Avoid highly polar solvents (Acetone,

MEK, etc.) and direct exposure to ozone and sunlight.

Temperature Range: –50°C to 100°C

Hydrogenated Nitrile (HNBR)

Description: HNBR is obtained by partially or fully

hydrogenating NBR, leading to considerable improvement of the resistance to heat, ozone, and aging.

Temperature Range: –40°C to 120°C

Standard Fluoroelastomers (FKM)

Description: FKM compounds provide excellent

resistance to petroleum products and solvents,

delivering very good high-temperature performance.

Limitations: Avoid polar solvents, amines, anhydrous

ammonia, SKYDROL, hydrazine, and hot acids.

Temperature Range: –20°C to 200°C

Low Temperature Fluoroelastomers (FKM)

Description: Like the standard fl uoroelastomer, the

low-temperature compound has excellent resistance

to petroleum products and solvents, and very good

high-temperature performance; but in addition, there

is an extended low-end temperature advantage.

Limitations: Avoid polar solvents, amines, anhydrous

ammonia, SKYDROL, hydrazine, and hot acids.

Temperature Range: –40°C to 200°C