Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Step One: Besure that the installation opening of the

housing is clean and clear of burrs, scratches, and dust.

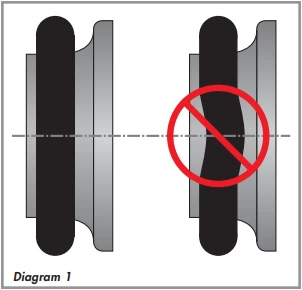

The O-ring must be correctly fitted on the floating seal

without distortion

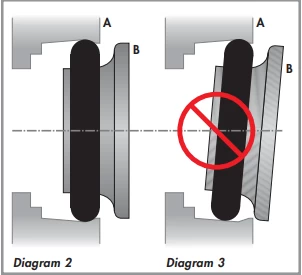

Step Two: Install the fl oating seal with the properly fitted

O-ring in the housing (Diagram 2). At this time, confirm that the end of the housing (A in the diagrams) will be

parallel to the sliding surface of the floating seat (B).

If the seal comes out of alignment, even partially

(Diagram 3), abnormal wear and deformation of the

O-ring will result, shortening the service life of the seal.

Step Three: After insertion, make sure that the sliding

surfaces are absolutely free of foreign matter, then

lightly apply lubricant oil to the sliding surfaces. Upon

completion of the seal installation, reassemble the

housings and fill with lubricating oil.

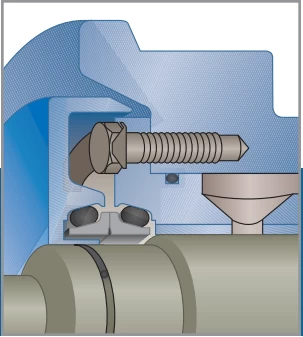

When properly installed, the two mated metal surfaces

seal against each other for maximum sealing. A thin

film of lubrication between the surfaces minimizes

wear. The O-ring energizers provide pressure to

ensure positive sealing.