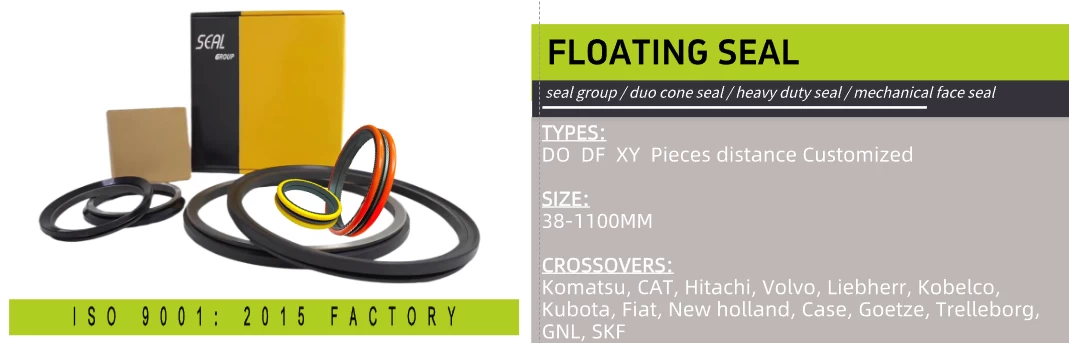

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

The following are the methods for selecting appropriate floating oil seal materials and applicable temperature ranges according to actual working conditions: