Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

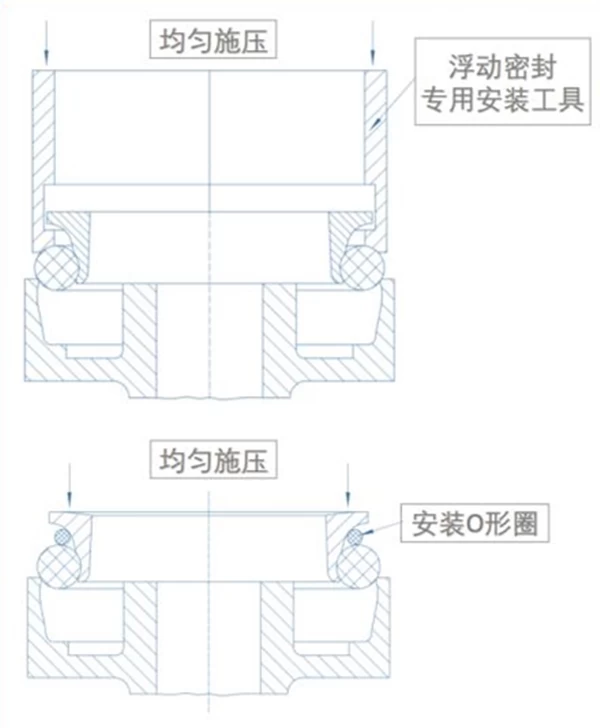

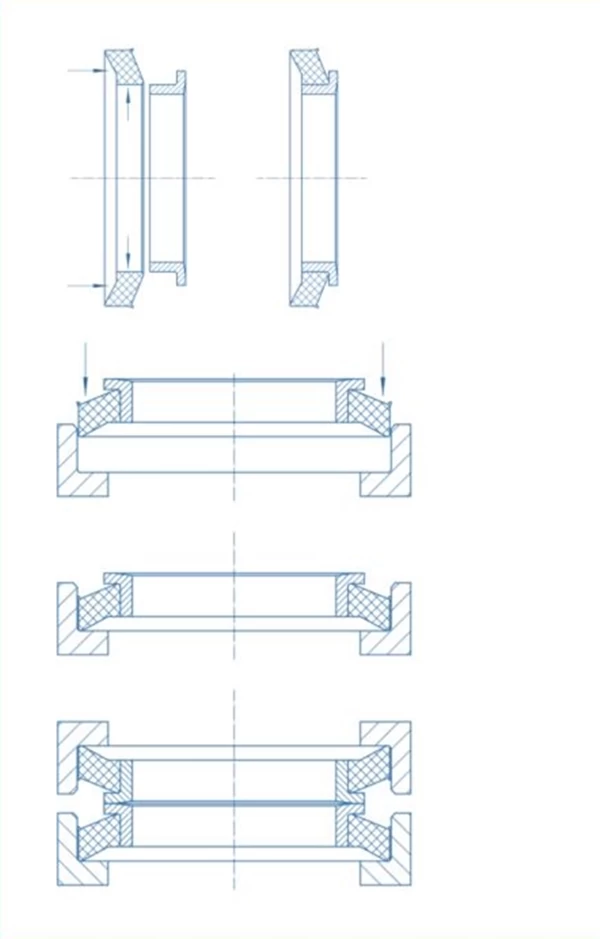

In order to ensure that the installation is accurate and in place during installation, it is required to install horizontally downwards, avoid tilting, vertical or upside-down installation. As shown in the figure, it is recommended to use the installation tool, put the installation tool on the outer circle of the floating seal ring, align the O-ring horizontally with the entrance of the floating seal seat chamber, and apply pressure to the installation tool gradually. The installation tool keeps the O-ring at the bottom of the back cone of the floating seal ring to keep its outer diameter small. In this way, the O-ring can slide into the floating seal seat chamber relatively easily. And avoid the sealing surface and O-ring being scratched. When the installation tool is lacking, a thinner and harder O-ring can also be used instead of the installation tool.

Check the position of the O-ring to make sure it is level and not twisted or arched. If so, need to adjust and restore. Check the parallelism between the sealing surface of the floating seal ring and the installation datum plane of the floating seal seat. Generally, the deflection shall not exceed 1/2000 of the outer diameter of the floating seal ring. Apply a clean lubricant film evenly on the sealing surface. When the equipment is aligned, it should be steady and gentle, and the sealing surface should not be damaged.

After the equipment is assembled, add lubricating oil according to the requirements, and test it for about 2 hours to check the oil temperature and the sealing parts for leaks and abnormal sounds.