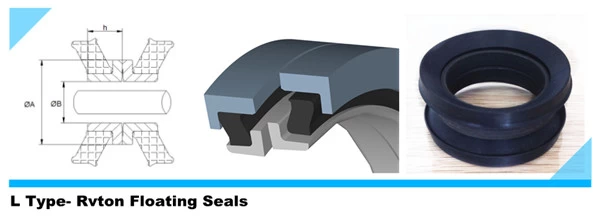

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

There are many types of oil seals, different materials and different performances. The floating oil seal is a relatively special oil seal. This oil seal is relatively new. Its main function is to apply these parts of the moving walk in mechanical equipment. The wear of the oil seal is more serious. The service life of the common oil seal is very short, not durable, and often needs to be replaced.

The floating oil seal is a new oil seal developed by the industry for this kind of use environment. It is very different from the traditional oil seal. The floating oil seal is mainly sealed by the pairing of two round seals. One seal is fixed and one can be rotated. When the equipment is running, the rotatable seal is followed by the machine. There is elastic attraction between the two seals. Although the wear of the oil seal is serious, the floating oil seal can obtain a certain amount of wear release and reduce wear damage after the wear of the elastic energy. Therefore, it is relatively wear-resistant and has a long service life. The service life of an ordinary floating oil seal can also be as long as 5000 hours or more. That is to say, if a mechanical device is to be operated continuously for more than three months, the oil seal will be damaged.