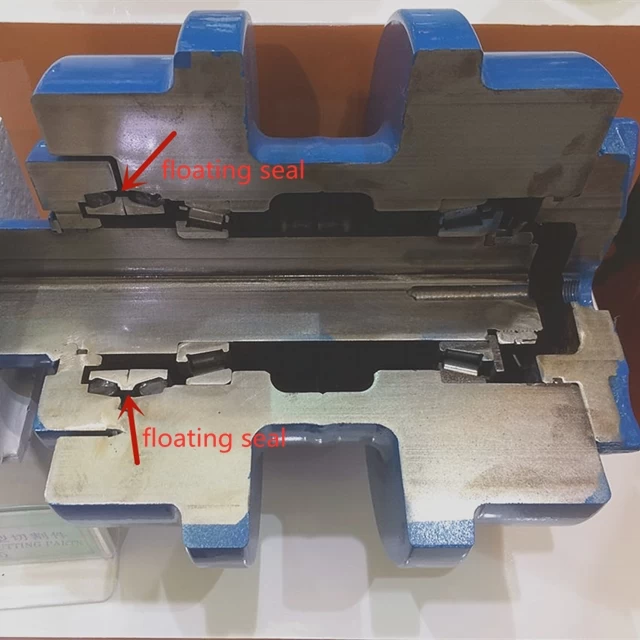

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

The daily maintenance of the floating oil seal only needs to be carried out on the equipment and does not need to be removed from the equipment. During routine maintenance and inspection, remove the dirt and oil on the surface of the oil seal in time, and clean the vicinity of the oil seal.

When the equipment is maintained for 2000 hours, check the wear of the oil seal, and replace the oil seal that is seriously worn and does not meet the requirements for use. Because when the oil seal wear becomes more and more serious, it will have an adverse effect on the bearing, resulting in excessive bearing clearance, deterioration of equipment operating conditions, increased load, impeded operation, and accelerated bearing fatigue damage.

Second, adjust the bearing clearance. Because the increase in the bearing clearance will aggravate the wear of the seal and the bearing. When the gap increases, the fit between the bearing and the floating oil seal is not tight, which will increase the possibility of external debris entering between the sealing surfaces, which will lead to increased wear of the sealing surface. Such a vicious circle will cause the floating oil seal to suffer Damage and seal failure.

Therefore, daily attention must be paid to strengthen the maintenance of the floating oil seal, adjust the bearing clearance correctly, protect the bearing and the floating oil seal, and prevent oil leakage.