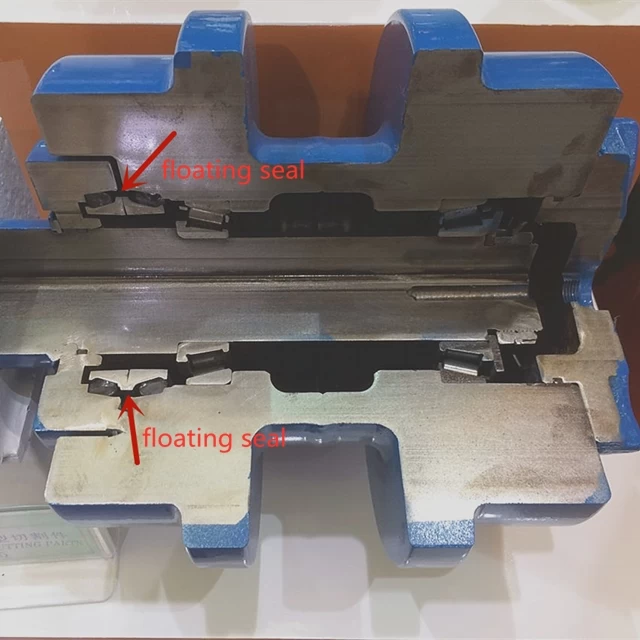

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

1. When installing the floating oil seal, the appearance of the floating oil seal needs to be inspected first to ensure that there are no impurities in the bearing before the inspection can be carried out. If impurities appear during use, the installation cannot be carried out normally. At this time, the impurities need to be cleaned up before installation.

2. The position of the rubber ring should be ensured during the installation process, so that the frictional force can be reduced when the floating oil seal is used, and the service life of the floating oil seal can be improved. Of course, when installing the rubber film, pay attention to placing a layer of oil film in the rubber ring to better increase its service life.

3. When installing the floating oil seal, pay attention to the tightness of the floating oil seal to ensure normal use.