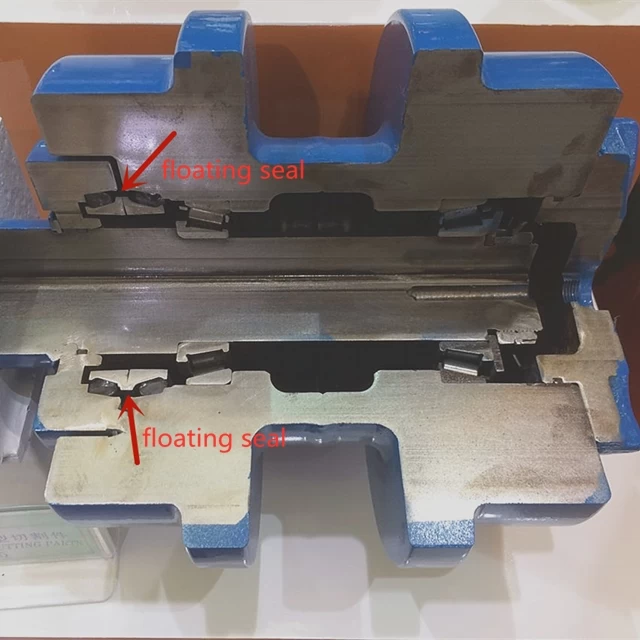

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

When the alloy floating oil seal is in use, you can check whether the floating oil seal can continue to be used according to the position of the observation contact zone. Experienced workers can also estimate the remaining life of the floating oil seal. If the floating oil seal is greater than half of the distance, it can still be used, otherwise it should be replaced in time.

The cast iron floating oil seal can automatically compensate for normal wear during use. The width of the sealing surface is between 0.5-1 mm. If wear occurs, the contact belt will move to the inner diameter and move slightly. A spherical surface is worn out.

During use, if the floating oil seal is severely worn, it will affect the normal operation of the mechanical equipment, so when it is found to be severely worn, it must be adjusted or replaced in time to ensure the normal operation of the equipment.