Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

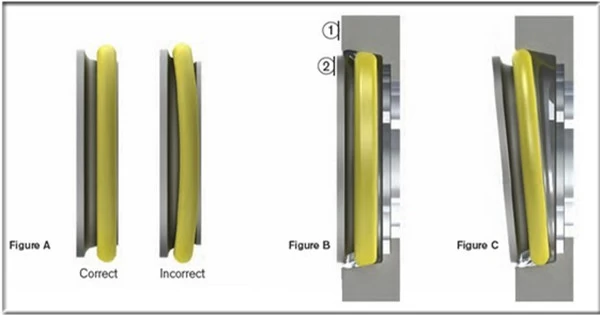

1. Before installing the floating seal, you can check whether the surface of the journal is too rough and there are no scars, especially if there are long scars along the axial direction. If the surface of the journal is too rough, it is easy to damage the oil seal and destroy its sealing performance. If the surface of the journal is improperly disassembled, it will cause more serious blunt marks, which will make the oil seal lip and the surface of the journal not fit tightly, causing oil leakage. If the journal has only metal burrs or flashing of the shaft head, it can be smoothed with a file to prevent the oil seal from being damaged when the oil seal is installed.

2. Check the oil seal lip for breakage, cracking or oil corrosion. If there is any such bad phenomenon, replace the new oil seal.

3. In order to prevent the floating seal lip from being deformed by stretching or scratching, a special installation tool is used. If you do not have this tool, you can first roll a transparent hard plastic film on the journal or even the shaft head, apply a little oil on the surface, seal the oil seal into the shaft of the plastic film, and seal the oil evenly. Push slowly onto the journal and pull out the plastic film.

If you have any questions, please feel free to contact us!