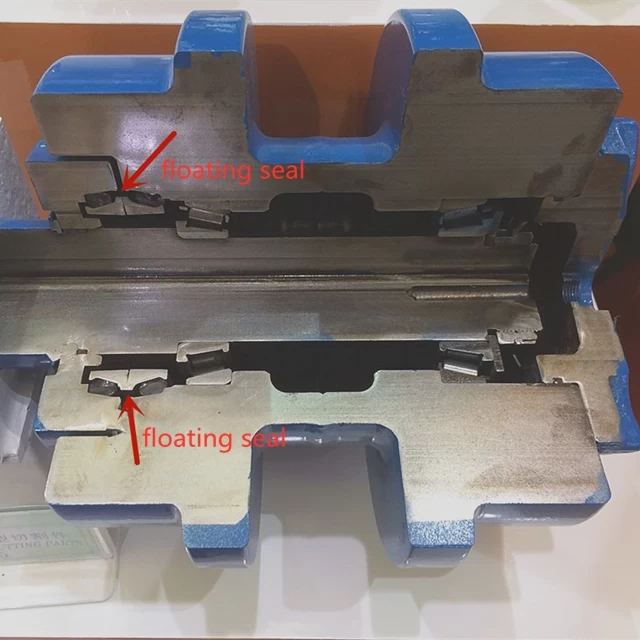

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Floating Seal is a Seal Used in Rotating Body Exposed to Silt and Sand.The Floating Seal Is a Kind of A Combination Seal Composed of High Hardness C ...

Maintaining the cooling state of the floating oil seal is to maintain the normal shape of the seal. Under low speed, light lubricating oil, when the internal and external pressure difference is large, the axial clearance or the swing is large, the contact surface specific pressure is usually increased to ensure the seal Reliable. Under high-speed conditions, the lubricating oil will be thrown away from the sealing surface under the effect of centrifugal force, making the sealing surface lack of lubrication, and the centrifugal force will raise the sealing surface of the floating seal ring and roll up, increasing the angle of the back cone surface, so that the sealing surface contacts the specific pressure Increase. Both of these reasons can easily cause the sealing surface to burn out.

Therefore, under the conditions of high linear velocity or high ambient temperature, it is usually selected to reduce the contact surface contact pressure. The maximum linear velocity of the floating oil seal is generally no more than 1m/s for the bearing seal ring of the bearing steel, and no more than 3m/s for the cast seal ring, and it varies according to the material of the seal ring. This is a control method to ensure the cooling state of the floating oil seal.